Share this article

Share this article

Today, across industries, companies are investing in R&D to find new ways to become environmentally friendly and improve sustainability in construction. This trend is particularly relevant for the construction industry which produces 40% of the world’s carbon emissions, and 23% of air pollution in the US alone as a result of industrial processes, infrastructure, and transport. Furthermore, the EU reported that its largest source of waste comes from construction and demolition waste. With increasing strict regulations around greenhouse gas emissions, companies can implement innovative tools to help them support corporate sustainability.

National governments are the key purveyors of environmental standards which often result in major value chain disruptions. As the actors overseeing the health, safety, and environmental conditions of the construction industry, governments, sometimes inadvertently, support the transition towards the increased development and diffusion of technology.

As governments continue to tighten environmental regulations and set ambitious goals, they also find ways to promote corporate sustainability in construction. In the United Kingdom, the government is tackling the high-cost barrier to making more sustainable choices. Specifically, the British construction industry must reduce its level of greenhouse gas emissions by 50% in the built environment by 2025. In order to reach this target, the government aims to reduce both the initial cost of construction as well as the whole-life-cycle cost of assets by 33%.

Meanwhile, in Singapore, the government is focusing on subsidising the cost of innovations that will reduce the industry’s environmental impact. Thanks to the Construction Productivity and Capability Fund, companies are partly reimbursed for the cost of:

By subsidising technology and eliminating the barriers to adoption, and promoting technology, such as BIM and remote, video-assistance tools, national governments can leverage their power to support sustainability in construction.

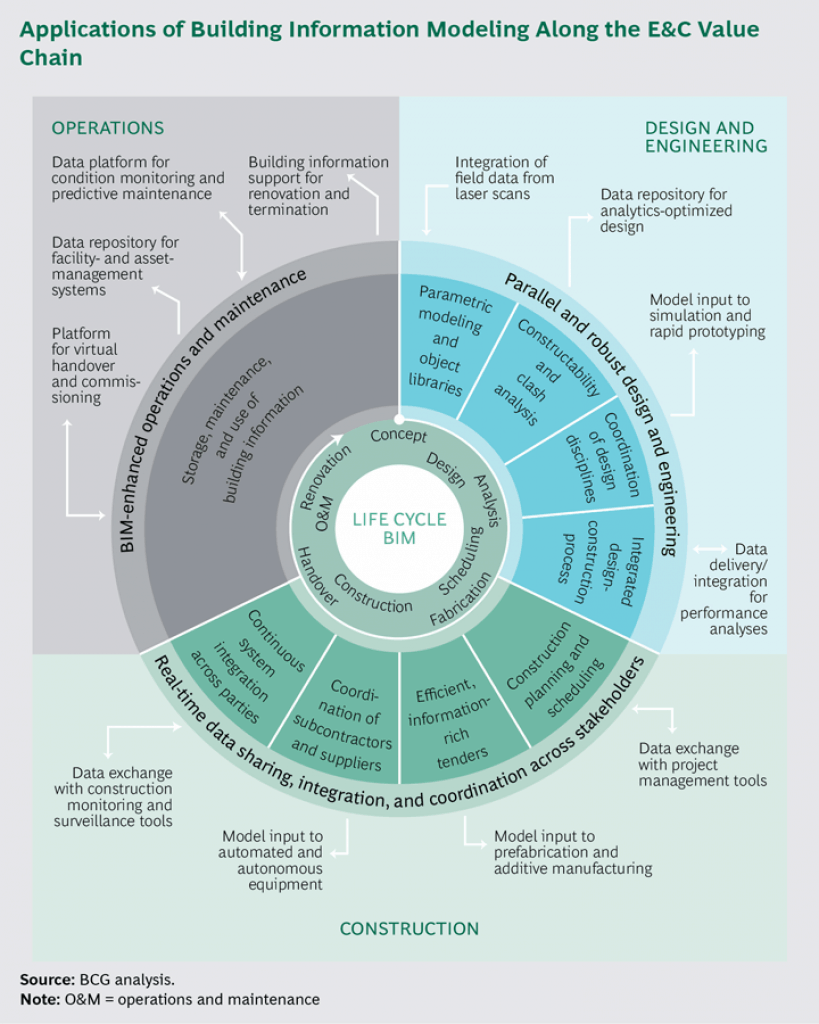

BIM allows a project to be modelled in its entirety using a 3D digital model. Using this technology, companies can calculate the environmental impact and energy performance of a project before the construction begins. BIM facilitates collaboration between the various stakeholders resulting in large efficiency gains. Concretely, this is because BIM allows for the collection and sharing of information in real-time in order to identify and map failures, wear and tear, and deficiencies. As a result, teams can operate while optimising equipment management to ensure energy efficiency and boost sustainability in construction.

An illustrative example: Sera Architects and Hoffman Construction, two firms based in Oregon were working jointly on a hotel renovation. They conducted a BIM-based energy analysis early in the design stage and achieved 30% in energy savings for ongoing operations and a 29% return on sustainability expenditures. BIM is proven to have links to greener construction planning; however, it can also be deployed throughout the life cycle of a project, as seen in the above graphic, to maximise energy efficiency and sustainability in construction. This can be combined with the use of remote, visual communications to enhance the collaboration between teams both on- and off-site.

When construction workers face technically-complex issues on-site, they may need to call a specialised expert or technician for assistance. However, with traditional voice-communications, the worker may be frustrated at his or her inability to properly describe the complicated situation which may lead to inaccurate solutions and further breakdowns. As a result, the expert may be forced to travel on-site, thereby producing excess carbon emissions.

Video-assistance solutions optimise communications between construction project teams. With an immersive view into a situation, and collaborative tools such as the ability to annotate documents and snapshots, and project a red laser onto the other caller’s live video feed, experts can easily diagnose and solve issues remotely. By solving problems from a distance with video-assistance tools, companies can reduce tech dispatch rates by up to 20%. This is a user-friendly and efficient way for companies to work towards meeting stricter emissions regulations.

As governments impose new regulations on emissions and waste across sectors, the construction industry is particularly impacted by these decisions. Corporate social responsibility is now a central tenant of operational strategies, and companies are increasingly looking to tech developments to meet these new demands. By integrating BIM and remote-video solutions throughout the value chain, companies can improve their operational efficiency, minimise the need for tech dispatch to resolve on-site problems, and reduce their carbon footprints. With the help of these solutions, improving sustainability in construction is more feasible than ever.