Share this article

Share this article

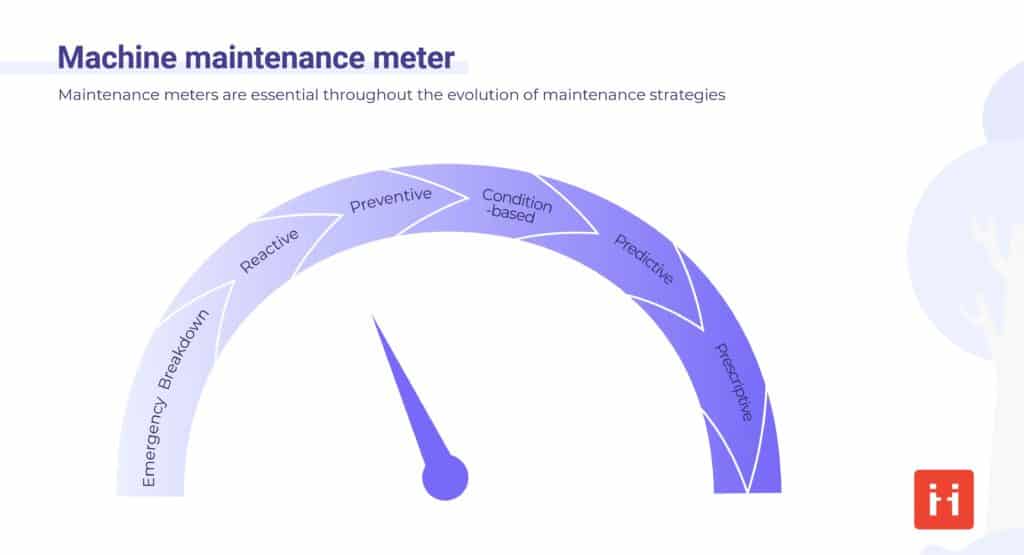

If you’re looking to refine your planned maintenance strategy, adopting a meter-based approach is worth considering. Unlike more limited strategies, such as time-based models, meter-based maintenance can be applied more generally. Although it requires a little more investment and adaptation than simpler models, meter-based maintenance can help you significantly reduce downtime and ensure you have all the resources to hand to implement business-critical fixes.

Meter-based maintenance refers to maintenance that is carried out based on triggers from meter readings. A maintenance meter can be used to measure a variety of variables. In the manufacturing industry, these variables can include the total number of products produced. Other variables can include the total time a piece of machinery has been in constant use, as well other conditions like operating pressure.

As it is a form of planned maintenance, meter-based maintenance can be applied to both predictive and preventative strategies. Meter-based maintenance isn’t the most straightforward of approaches. This is largely down to the fact that meters need to be interpreted before any maintenance can occur. However, provided a meter is referred to regularly and CMMS software is utilized, maintenance can be scheduled and carried out effectively.

Meter-based maintenance, otherwise known as performance-based preventative maintenance, implements broad data tracking to determine the scope of maintenance deployed. Meter readings keep track of usage variables providing you with the best maintenance insights for your equipment.

If your operation requires a significant commitment to maintenance it makes sense to inappropriate meter-based maintenance along with other methods, such as asset tracking and condition-based maintenance. This is particularly important if you have different types of equipment that have unique maintenance requirements. Not every company shares the same priorities when it comes to balancing up potential repair costs with the assurance of trouble-free operation of their assets.

A preventative maintenance strategy is the way to go if you’re looking to improve the operational life of your assets, keep downtime to a minimum, and significantly slash the cost of maintenance and repairs. Smaller companies are often drawn to reactive maintenance models, seeing this approach as both cheaper and easier to implement. However, reactive maintenance can be ineffective in the long run, as overall costs can quickly mount up. Provided a preventative maintenance program is properly planned for, it can be a cost-effective and user-friendly solution.

CMMS software can significantly improve your preventative maintenance strategy. The right CMMS software can ensure the most rigorous preventative maintenance standards are being adhered to. What’s more, accessible CMMS software ensures all relevant stakeholders can take an active role in preventative maintenance.

Integrating preventative maintenance with computerized management software also allows you to create tailored maintenance checklists that technicians and experts can follow. These checklists not only provide step-by-step guidance to eliminate human error but can also be used to provide clear oversight of previous work that might have been carried out. What’s more, these checklists allow for maintenance operatives to provide detailed feedback to supervisors. This information can be used for future maintenance planning and to streamline the implementation of future fixes.

The applications of CMMS software have come a long way in recent years, thanks in no small part to IoT technology. IoT asset management makes use of reliable sensors to collect data, allowing maintenance technicians and supervisors to monitor the performance and condition of assets effectively. These sensors not only track data but can also relay it to the Cloud and any connected CMMS systems.

IoT sensors keep track of variables like usage, but can also monitor slight variations in equipment temperature. By defining limits within a CMMS, you can ensure maintenance work orders are triggered should any variables cross these pre-set thresholds.

Meter-based readings are an effective way of implementing a preventative maintenance strategy. If your organization relies on machinery, vehicles, or any other type of asset that needs to operate continuously, maintenance meters are crucial.

Unlike time-based maintenance strategies, which can often result in maintenance being scheduled too late or early, a meter-based approach allows you to effectively utilize asset data to improve efficiency, minimize downtime, and eradicate unnecessary expenditure.

Free E-book available now!